Dental Machine

“All smiles for the dental equipment manufacturer thanks to our custom LED assembly”

Industry

Medical

Dermatology

Expertise

Design Consulting

Products/Services

Standard Product

Nearshore Manufacturing

Water-resistant PMI

Build Your Own Indicator

Application Characteristics

As leading-edge dental devices become smaller and more portable, they must maintain the same level of safety, cleanliness, and performance as their more stationary counterparts — many requiring custom design solutions for their illuminated components.

When our client approached us with a long list of requirements for its dental device, we quickly provided a solution that met all client objectives and then some.

Application Requirements

For this water laser machine, the list of illumination design requirements was quite extensive:

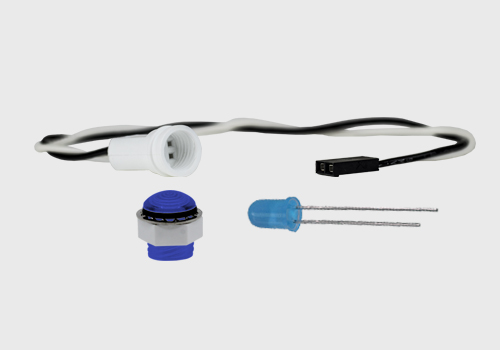

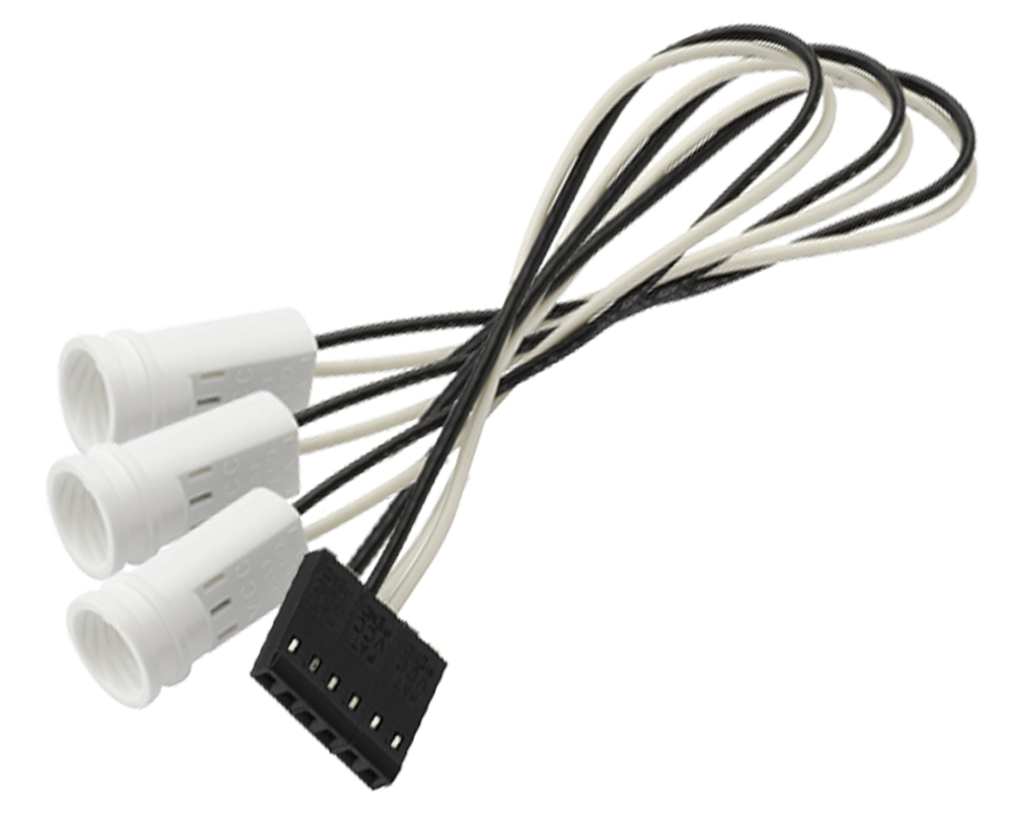

The design called for a custom cable assembly with three LED socket assemblies

Each of the socket assemblies would house removable LEDs

The LEDs had to be easy to install through the front panel

There was an isolation requirement to prevent the LED to excess water exposure

The device needed to withstand constant exposure to water and cleaning solutions

Our engineers worked closely with the client to develop the ideal solution.

“Our build your own indicator option delivered a custom, cost-effective LED assembly solution with three replaceable and LED socket assemblies.”

Caleb Hwang

Mechanical Engineer, VCC

Solution/Approach

Build Your Own Indicator

Using the build your own indicator option, which allows for customization of design using standard sizes and parts, we configured a solution that customized LEDs, wire size, length, color, and wire termination for the client.

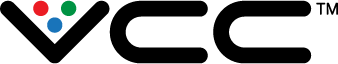

CNX440 5mm Panel Mount Indicator

Our team specified the CNX 440 Series cable assembly for its quick and easy connections between panel–mounted LEDs and the power source. We then integrated the assembly onto a custom cable with three replaceable LED sockets and added high-output, waterproof lenses.

CMS442 Lens

For this application, the blue CMS442 lens was used with the cable assembly. This threaded Fresnel lens includes a watertight seal due to a retaining ring and lock washer. With a NEMA 6P rating, the lens is protected from constant exposure to moisture from water and cleaning solutions.

Lenses are also available with clear and diffused lens, flanged and flangeless, multiple viewing angles, and various colors, including green, red, white, and yellow.

“Watertight status was a priority for the safe operation of this dental device, and we attained a NEMA 6P rating with a threaded Fresnel lens, retaining ring and lock washer.”

Omar Lara

Sr. Process Engineer, VCC

Results & Benefits

Enhanced safety and long bulb life

By providing a solution that included a long-lasting LED that was isolated from exposure to water, we helped ensure safe operation for years to come.

Custom indicator without additional cost or production time

The “build your own indicator” option delivered the exact specifications without the costs or production time associated with a custom-made product.

Enhanced productivity and profitability for the dentist

With an easy-to-use illuminated solution that quickly communicates with the operator through visual indication vs. text, dental teams can perform faster treatments, thus enhancing productivity.

Better dental experience for patient

The portable device with advanced water laser technology speeds up the process while eliminating pain during treatments that would otherwise require a drill.

Value-Added Services

At VCC, we pride ourselves on having a seat at the table for designing medical technologies that improve the lives and safety of patients worldwide. Our custom cable and three-socket configuration quickly and efficiently provided the client exactly what was needed for its innovative device. Plus, we helped the client maximize efficiency and reduce production costs through using the build your own indicator option and nearshore manufacturing.

Explore Case Studies

Medical Device

Learn how we created a custom light engine and PCB assembly for a medical device while slashing production time and costs.

Healthcare Simulation Device

Discover how VCC’s standard indicator helped an innovative manufacturer crack the code on a healthcare simulation device at a fraction of the cost.

Sanitizing Device

See how VCC’s capacitive touch sensors delivered the ideal HMI solution for a sanitizing device that utilizes UV-C rays.

Panel Mount Indicator

LED Watertight PMI Build Your Own Indicator Neon Incandescent More

Circuit Board Indicators

LEDs

Latest Products

Check all the Latest Products

Custom Wire Harness

Custom Solutions

Custom Design Capabilities

Technical Resources

Product VideosBrochuresCustom SolutionsNewsCase StudiesFAQsGlossaryVideo Webinar

Purchasing

Product

Videos

Learn more about our products

The Latest

Contact

Contact Us

Call Us 1.800.522.5546