When it comes to choosing the right PMI for the job, several questions come to mind. And if your device will be operated anywhere other than a dry, pristine work environment, protecting it from exposure to a range of contaminants is a top priority.

Harsh Environments Aren’t Limited to Outdoor Applications

Devices can face a host of potentially destructive elements in applications ranging from food service and medical devices to industrial equipment, including:

- Dirt

- Sweat

- Dust

- Debris

- Grease

- Water

- Cleaning chemicals

- Blood (hopefully only in medical applications!)

With so many potentially harmful things coming at a device in a given workday, there are steps designers and OEMs can take to protect their indicators and ensure safe, reliable and durable operation for years to come.

The first question to address is, What IP Rating do I need?

Or maybe it’s What’s an IP Rating?

Either way, VCC has you covered. Let’s start with the basics.

IP Ratings Overview

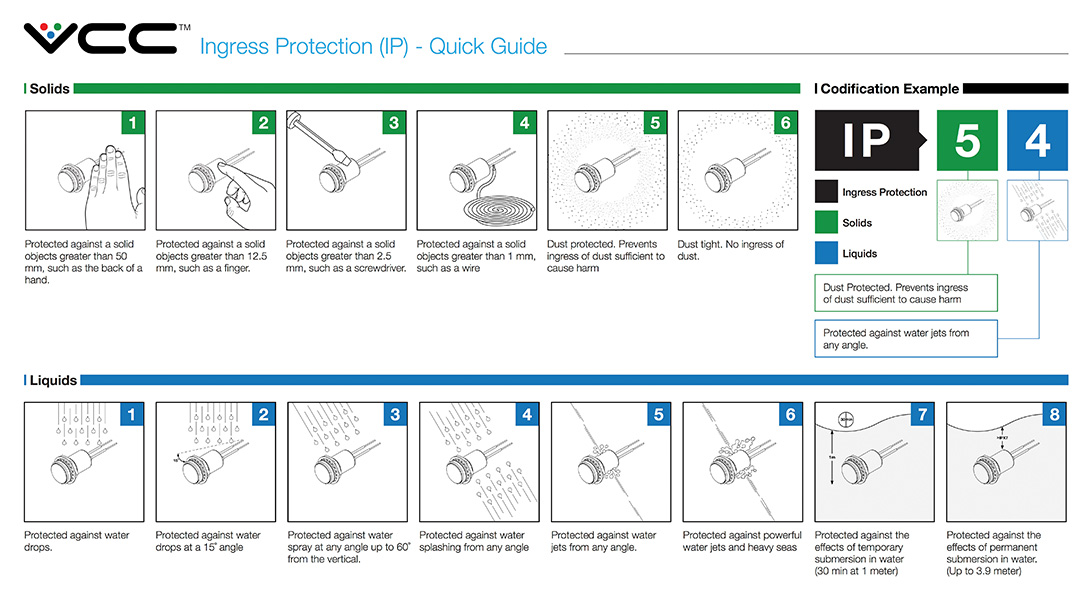

To indicate component protection levels, we use IP ratings. IP ratings, known as Ingress Protection or International Protection ratings are numerical scores used to communicate the levels of sealing effectiveness against intrusion from dirt, water and other foreign bodies.

Here’s a quick reference guide of what the various IP Ratings mean:

Ingress Protection

Solids

The first digit communicates the degree of protection from foreign bodies.

Liquids

the second digit indicates protection level from various forms of moisture (drips, sprays, jets and immersion).

Typical IP Ratings for Common Applications

The IP Ratings of our extensive PMI portfolio will vary, but most of our solutions fall within the following ratings suitable for a wide range of applications:

- IP65 – dust tight and protected against water projected from a nozzle.

- IP67 – dust tight and protected against complete, strong water jets and waves.

It’s easy to assume a higher IP rating is needed for outdoor use, mainly because of exposure to rain. But raindrops don’t fall with enough pressure to always warrant extensive protection. Be sure to work with your manufacturer’s engineers to identify the most appropriate level of protection for your device.

Close attention should also be paid to operating temperatures, as these can affect the performance and longevity of a device.

IP Ratings in Action

IP Smart Dog House: IP67

A dog house may seem pretty simple, but this smart dog house includes a webcam, climate control, and constant communication with a mobile app. Exposure to Boomer’s business is about as harsh as it gets. So this intelligent dog house must withstand dirt, moisture and everything it may encounter outdoors. VCC used moisture-sealed CNX714 and CNX722 PMIs with FlexVolt all-in-one technology to enable safe and reliable operation in any condition.

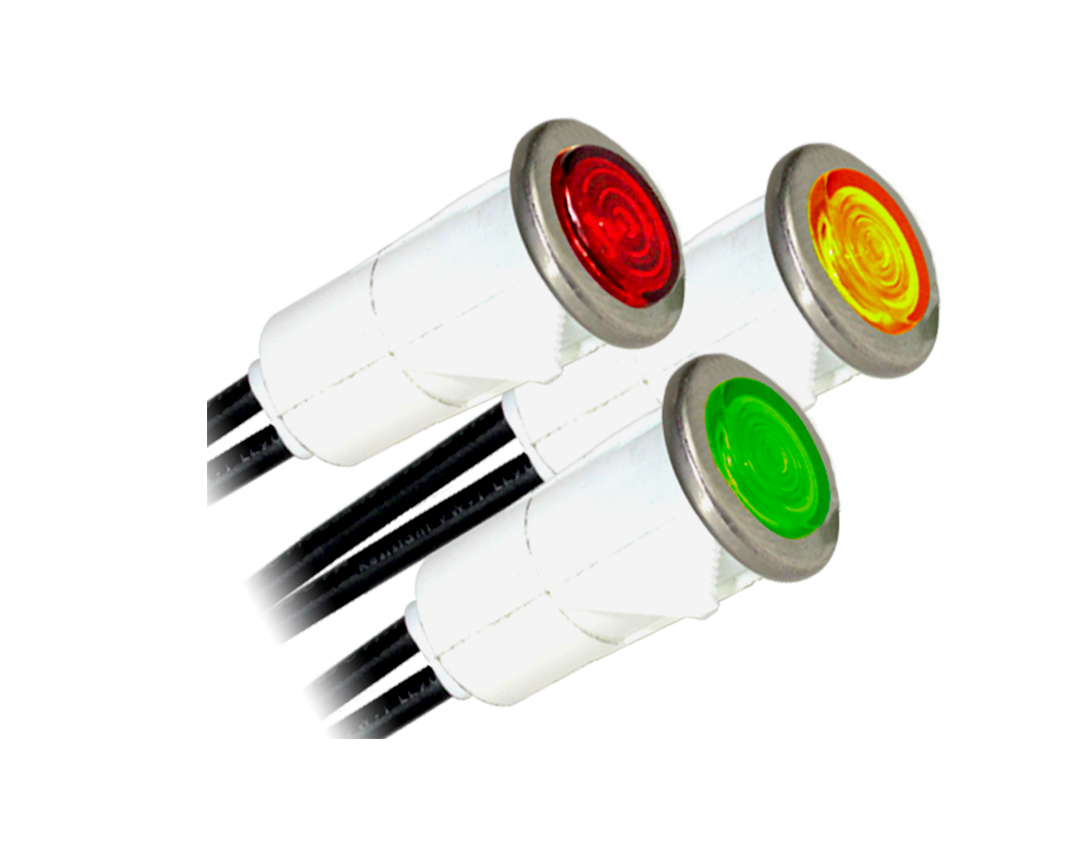

Self-Serve Pizza Warmer: IP65

You may not think a pizza warming cabinet designed for self-service pickup is a harsh environment. However, exposure to grease, moisture and cleaning supplies requires a watertight solution. In this case, red and green PCL22 Series PMIs were used to provide reliable performance and a wide viewing angle while protecting the panel from a range of harmful materials.

Power Generating Station: IP65

With thousands of customers relying on electricity, downtime isn’t an option for electrical power generating stations. Control panels provide crucial status indication that helps ensure uptime and quick response to any issues. With a control panel that’s constantly exposed to weather and the elements, a watertight, screw block PCL22 Series LED with a lock washer and hex nut was used to deliver dust and watertight-performance for enhanced reliability.

Power Factor Correction Capacitor: Moisture Protection

Sometimes, all it takes is an extra piece of hardware to produce the desired level of moisture protection on any PMI. This power factor correction capacitor required a ruggedized solution to accommodate the steel HMI made for outdoor use. VCC recommended the 981 Series snap-mount indicator with an additional gasket to provide the precise moisture seal required for the task at hand.

Other design considerations for harsh environments:

Body length

for heavy-duty applications the control panel itself may need to be constructed using thick steel to deliver maximum protection from the elements. A long body can help accommodate the design requirements for a more robust HMI.

Vibration Protection

many design elements can impact vibration resistance and keep the PMI in place, from the type of body itself to the mounting style and any additional hardware. For example, the PML50 Series PMI uses a “Double-D” mounting style to make sure the indicator stays put in high-vibration applications. Other solutions include an O-ring, gasket, which may or may not be included with the PMI itself. Inquire with your designer or distributor for product-specific details.

UV Protection

moisture and weather make outdoor conditions harsh enough. But the sun’s harmful rays can also have an impact on status indication. Solutions like the PML50 Series waterproof PMI combine the protection of an IP67 Rating with the UV-shield to eliminate fading and discoloration.

Body Type

all VCC PMIs with metal housings bring anti-rust and corrosion resistance to the table. They also guarantee supreme protection from dirt, grease, intense wash-downs and anything else the job throws your way thanks to an IP67 Rating.

In addition to reliable operation in harsh environments, many of VCC’s ruggedized PMIs deliver efficiencies in manufacturing and assembly, which can drive down overall production costs.

Check out our collection of ruggedized panel mount indicators in our brochure

Contact UsHarsh Environment BrochurePanel Mount Indicator

LED Watertight PMI Build Your Own Indicator Neon Incandescent More

Circuit Board Indicators

LEDs

Latest Products

Check all the Latest Products

Custom Wire Harness

Custom Solutions

Custom Design Capabilities

Technical Resources

Product VideosBrochuresCustom SolutionsNewsCase StudiesFAQsGlossaryVideo Webinar

Purchasing

Product

Videos

Learn more about our products

The Latest

Contact

Contact Us

Call Us 1.800.522.5546