Custom Light-Pipes Deliver LED Illumination Where Needed for Panel Indicators and Displays

LEDs have become the light source of choice for many indicator applications in control panels, automotive in-dash electronics systems, consumer electronics devices, and medical and industrial equipment. In many cases, they are replacing bulkier, less efficient incandescent light sources that are less reliable than modern LED indicators. In some of these types of applications, mounting a PC board with a packaged LED on the backside of the front panel is impractical or inefficient because of space constraints, thermal considerations, or electrical layout parameters. Hence, the development of light pipes (also called light guides) as a means of transporting the light from a remotely mounted LED to the front panel or any other location where the indication or illumination needs to be visible.

Light pipes are composed of non-light absorbing optical grade materials with a high total internal reflection (TIR) rating, typically high-purity polycarbonate materials, cast acrylic resins such as polymethylmethacrylate (PMMA), epoxies, or high-grade glass. In their most basic form, standard light pipe configurations include straight, right-angled, or triangular-shaped cylindrical or rectangular tubes that fit on top of the mounted LED (or the lens of the LED package) and transmit the light to the outside of the enclosure. There are also standard light pipes constructed of flexible materials to fit irregular spaces or applications in which the placement of the mounted LED or the indicator may be variable.

Custom-Shaped Light Pipes for Specific Functions

Some applications require a custom-designed light pipe in order to fulfill a specific indication function. For example, a triple-legged custom light pipe might be designed to deliver indication signals from three separate LEDs, each representing a different status (green = all systems normal; yellow/amber = caution; and red = danger or warning). In such a design, the three legs of the light pipe would be fitted to each of the three mounted LED lenses, with the single end fitted to the enclosure or panel indication opening. Depending on the status condition, one of the LEDs would be illuminated and its light carried up to the outside of the panel.

Another example of when a custom-configured light pipe may be needed is if a serpentine path is required in order to transmit the light out to the enclosure’s exterior, as would be the case if there were large components between the mounted LEDs and the exterior surface. In such a case, the light pipe design would have to be done after the initial PC board layout was completed.

In other applications, it may be necessary to design a wedge- or curved-shape light guide to direct a planar array of LEDs mounted on a PC board to backlight a perpendicularly-mounted LCD or other display. This type of configuration allows designers to keep the LEDs mounted on the main PC board (typically on the horizontal plane), where the majority of the system’s electrical connections and heatsinks are located, yet allows them to backlight a vertically mounted LCD display without increasing the depth of the enclosure behind the display screen.

Technical Considerations when Selecting a Custom Light Pipe Design

A number of complex calculations are required in the design of a custom light pipe, including the light output of the LED light source; the reflective characteristics of the light pipe material itself; the method of mounting/affixing the LED to the light pipe; and how the light is transmitted through the exit surface on the enclosure’s exterior.

Two of the fundamental principles governing the calculations of the light pipe material are Snell’s Law, which describes the angle of refraction when a light ray crosses the boundary between two mediums, and Fresnel losses, which define the reduction in light when the light rays cross the boundary between mediums due to reflection from the surface. These and several other calculations are used to determine the total internal reflection (TIR) properties of the light pipe material and also take into account the number of bends in the light pipe, as well as their angles.

The mounting method of the light pipe to the LED itself (or the packaged LED lens) is also a consideration in the light pipe design. In general, the closer an LED can be mounted to the light pipe entrance, the more light will be transmitted through it. Thus, there are a number of mounting configurations possible where the light entrance of the light pipe features a concave recess that the LED (lensed or un-lensed) fits inside to enable more light to be captured within the light pipe.

For the exit transmission of light through the light pipe, and ultimately to the indication source on the exterior of the enclosure, consideration must be given to the specified viewing angle, brightness, and degree of diffusion (typically accomplished with an external lens.)

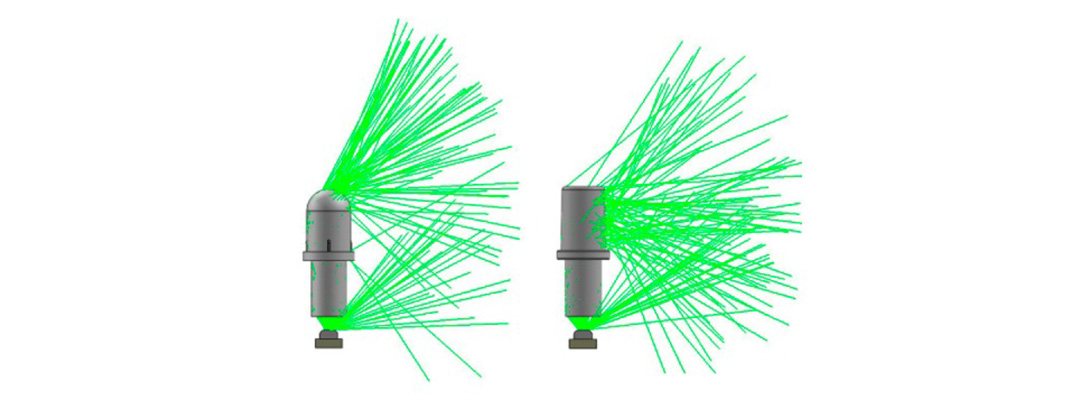

Light-Modeling Software Streamlines the Design Process for Custom Light Pipes

Leading light pipe manufacturers integrate light modeling software tools that incorporate angle of refraction and reduction in light calculations to enable the rapid simulation, modeling, and verification of custom light pipe designs. Use of these modeling tools speeds the time to market for custom designs and should be a key parameter when selecting a supplier for custom light pipes.